हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ पà¥à¤°à¥à¤¶à¤° à¤à¤à¤à¥à¤¨à¥à¤¸à¤¿à¤«à¤¾à¤¯à¤°

Price 110000 आईएनआर/ Unit

MOQ : 1 Unit

हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ पà¥à¤°à¥à¤¶à¤° à¤à¤à¤à¥à¤¨à¥à¤¸à¤¿à¤«à¤¾à¤¯à¤° Specification

- कनेक्टिविटी टाइप

- Hydraulic Port Connections

- फ्लो रेट

- Input up to 16 LPM, Output as per intensity ratio

- सीलिंग टाइप

- एप्लीकेशन

- Work Holding, Tyre Curing Press, Bolt Tensioning, Aluminum Die Casting, Injection Moulding, Hydraulic Fixtures, Clamping Systems

- पावर सोर्स

- ऑपरेटिंग प्रेशर

- Up to 700 Bar (10,000 PSI)

- एक्सेसरीज़

- Mounting Brackets, High Pressure Fittings, Hydraulic Hoses

- दक्षता

- High (>90%)

- माउंटिंग टाइप

- तापमान सीमा

- -20°C to +80°C

- उपयोग

- औद्योगिक

- बॉडी मटेरियल

- टाइप करें

- स्ट्रक्चर

- Cylindrical, Compact

- फ़ोर्स

- स्पीड

- High Speed (up to 60 cm³/min output)

- वोल्टेज

- Not Applicable (Hydraulic Driven)

- Intensification Ratio

- 4:1, 10:1, 20:1 (as per model)

- Output Port Size

- 1/4” BSP/NPT

- Noise Level

- <70 dB

- Safety Feature

- Integrated Pressure Relief Valve

- Surface Finish

- Hard Chrome Plated/Phosphated

- Corrosion Resistance

- Yes

- Size

- Customizable; Standard length 200-300 mm

- Cycle Life

- Over 1 Million Cycles

- Weight

- Approx. 5 – 12 kg (depending on model)

- Color

- Metallic Grey/Standard Machine Finish

- Input Port Size

- 3/8” BSP/NPT

हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ पà¥à¤°à¥à¤¶à¤° à¤à¤à¤à¥à¤¨à¥à¤¸à¤¿à¤«à¤¾à¤¯à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- 5000 प्रति महीने

- डिलीवरी का समय

- 7 हफ़्ता

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About हाà¤à¤¡à¥à¤°à¥à¤²à¤¿à¤ पà¥à¤°à¥à¤¶à¤° à¤à¤à¤à¥à¤¨à¥à¤¸à¤¿à¤«à¤¾à¤¯à¤°

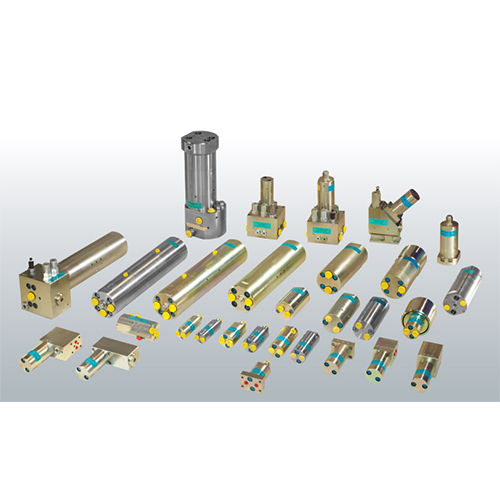

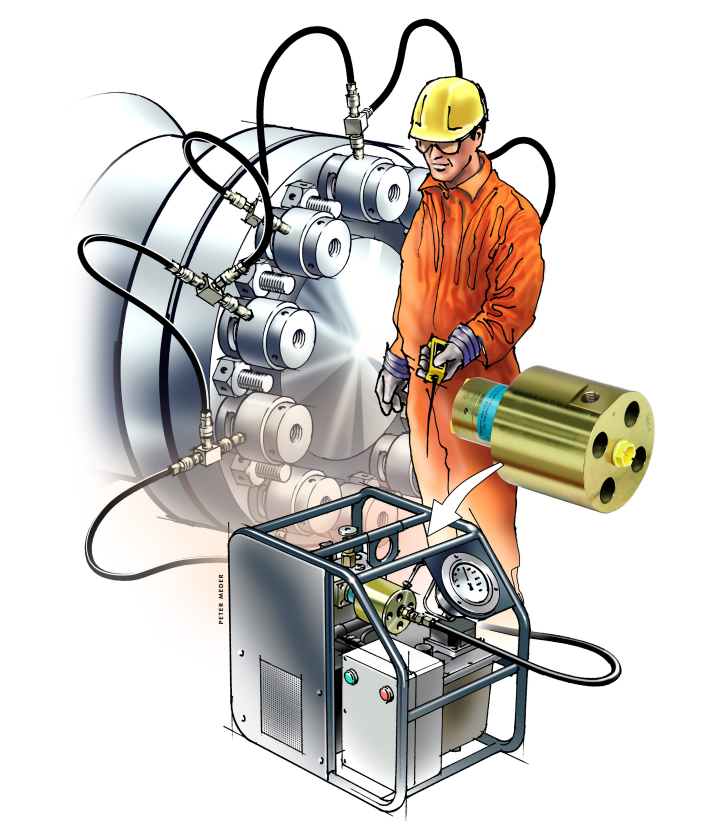

Presenting the new release Hydraulic Pressure Intensifiers in outstanding metallic grey or standard machine finish. These impeccably engineered devices offer customizable sizes (standard length 200300 mm) with grand intensification ratios of 4: 1, 10: 1, and 20: 1, delivering force up to 500 kN at high speeds. Procure unmatched durability with corrosion resistance, integrated pressure relief, and cycle life exceeding one million cycles. Redeem superior performance for work holding, tyre curing presses, bolt tensioning, and die casting. Crafted from high grade steel, these intensifiers guarantee grand efficiency (>90%%) and adaptability for various applications.

Versatile Hydraulic Pressure Intensifiers: Applications & Features

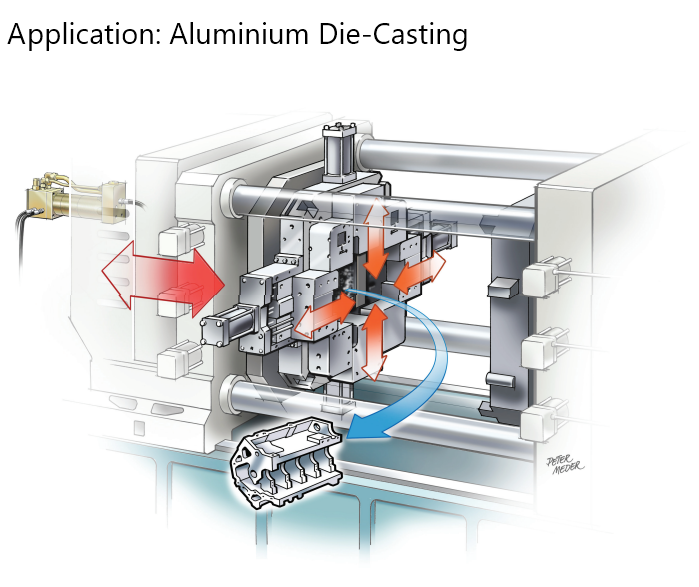

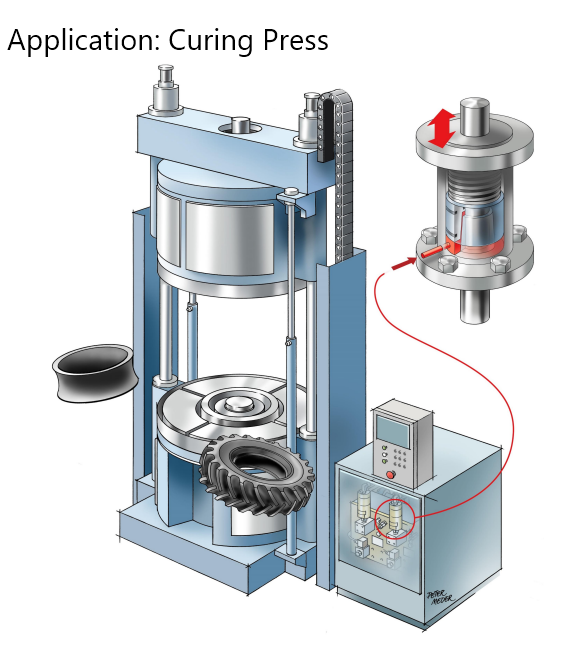

Our hydraulic pressure intensifiers are ideal for work holding, tyre curing presses, bolt tensioning, aluminum die casting, injection moulding, hydraulic fixtures, and clamping systems. Application is seamless via hydraulic port connections, complemented by mounting brackets, high pressure fittings, and hoses. Key features include high pressure seals, integrated pressure relief valve, hard chrome plating, and operation at up to 700 Bar. Their compact cylindrical structure ensures high output speed and efficiency, meeting diverse industrial needs.

Domestic & Export Supply Markets and Packaging Excellence

We supply hydraulic pressure intensifiers with stock ready for immediate dispatch across Denmark and major international markets. Our products are handed over securely, packed with mounting accessories to ensure safety during transit. The main export markets include neighboring European countries and global industrial hubs. Domestic demand is robust, with traders, distributors, and suppliers regularly replenishing inventories. Each unit is procured with efficient packaging, ensuring grand protection and timely delivery.

Versatile Hydraulic Pressure Intensifiers: Applications & Features

Our hydraulic pressure intensifiers are ideal for work holding, tyre curing presses, bolt tensioning, aluminum die casting, injection moulding, hydraulic fixtures, and clamping systems. Application is seamless via hydraulic port connections, complemented by mounting brackets, high pressure fittings, and hoses. Key features include high pressure seals, integrated pressure relief valve, hard chrome plating, and operation at up to 700 Bar. Their compact cylindrical structure ensures high output speed and efficiency, meeting diverse industrial needs.

Domestic & Export Supply Markets and Packaging Excellence

We supply hydraulic pressure intensifiers with stock ready for immediate dispatch across Denmark and major international markets. Our products are handed over securely, packed with mounting accessories to ensure safety during transit. The main export markets include neighboring European countries and global industrial hubs. Domestic demand is robust, with traders, distributors, and suppliers regularly replenishing inventories. Each unit is procured with efficient packaging, ensuring grand protection and timely delivery.

FAQs of Hydraulic Pressure Intensifiers:

Q: How do Hydraulic Pressure Intensifiers operate in industrial settings?

A: Hydraulic Pressure Intensifiers function by increasing input pressure to a higher output pressure, efficiently powering applications such as work holding, tyre curing presses, and bolt tensioning. Their compact and cylindrical design allows integration into various hydraulic systems.Q: What is the process for mounting these intensifiers?

A: These intensifiers can be mounted inline, on manifolds, or on panels using mounting brackets and high pressure fittings included with the unit, allowing flexible installation depending on the specific application and system design.Q: When should I use a Hydraulic Pressure Intensifier?

A: Use a Hydraulic Pressure Intensifier when your operation demands higher hydraulic pressure than what your supply system provides, especially in processes like aluminum die casting, injection moulding, and high-force clamping.Q: Where are your Hydraulic Pressure Intensifiers supplied and exported?

A: We supply and export to domestic markets within Denmark and major industrial hubs worldwide. Our distribution network supports traders, suppliers, and end-users across Europe and beyond.Q: What benefit does the integrated pressure relief valve provide?

A: The integrated pressure relief valve safeguards the system from overpressure, ensuring safe operation and enhancing the reliability and longevity of both the intensifier and the connected hydraulic equipment.Q: How efficient is the Hydraulic Pressure Intensifier?

A: Our Hydraulic Pressure Intensifiers boast a high efficiency rate of over 90%%, making them a grand choice for applications requiring consistent performance and low energy loss.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें